Carbon Footprint Reduction in the Coffee Supply Chain

Introduction to the Coffee Supply Chain Carbon Footprint

The coffee industry has a substantial carbon footprint, with impacts across its global supply chain. From farming and processing to roasting, brewing, and disposing of coffee, greenhouse gas emissions are generated at every step. As one of the world’s most popular drinks, reducing coffee’s environmental impact is an urgent priority.

This article will provide an in-depth analysis of the sources of carbon emissions across the complex coffee supply chain. It will also outline a range of practical strategies and innovations aimed at dramatically lowering the carbon footprint of producing, shipping, and consuming coffee worldwide.

Key Takeaways

- Significant Carbon Footprint: The coffee supply chain has a notable carbon footprint, impacting every stage of production, from farming to brewing.

- Emission Reduction Strategies: The article discusses strategies like sustainable farming, renewable energy, and eco-friendly packaging to lower coffee’s carbon footprint.

- Shared Responsibility: It emphasizes that all stakeholders, including consumers, play a role in reducing coffee emissions through conscious choices.

- Carbon-Neutral Goal: Transitioning to carbon-neutral coffee production is crucial to protect the future of this beloved beverage, requiring commitment and innovation across the supply chain.

The Carbon Footprint of Coffee Production

Coffee cultivation and harvesting contributes to deforestation, greenhouse gas emissions, water pollution, and other sustainability issues:

- Converting forests and wilderness to new coffee plantations leads to a substantial loss of carbon-sequestering trees and vegetation. This drives climate change through the release of carbon dioxide.

- The heavy use of synthetic fertilizers and chemicals releases nitrous oxide, a potent greenhouse gas with 300 times the warming potential of carbon dioxide.

- Pesticides and fertilizer runoff also pollute local soils, rivers, lakes, and oceans, damaging ecosystems and communities.

- At origin, coffee farms rely heavily on diesel generators for electricity, which have high emissions compared to cleaner renewable sources like solar, wind, or hydropower.

- Large amounts of water are consumed washing and processing coffee cherries. Wastewater and byproducts like discarded pulp create methane if left untreated in landfills.

Transitioning to Sustainable Coffee Farming

There are several ways to reduce the carbon footprint of coffee farming:

- Agroforestry systems with shade trees, ground cover plants, and nitrogen-fixing cover crops regenerate soil health naturally without synthetic fertilizers.

- Composting coffee pulp and farm waste to make organic fertilizer avoids methane emissions and chemical runoff while improving soil.

- Mulching, crop rotation, erosion controls, and water conservation further enhance soil quality and farm sustainability.

- Solar, wind, or hydropower can provide emissions-free electricity to replace diesel generators.

- Protecting existing forests and planting trees helps offset deforestation impacts.

With training and support, coffee farmers around the world can transition to regenerative practices that benefit both environmental and financial sustainability.

The Environmental Impact of Coffee Processing and Export

After harvest, coffee cherries undergo a series of energy-intensive steps to prepare green coffee beans for export. This includes milling, sorting, grading, washing, fermenting, drying, and bagging:

- Processing facilities use significant electricity, diesel fuel, liquefied petroleum gas, firewood, and other energy sources. Renewable solar, wind, or hydropower options are cleaner alternatives.

- Heating water and treating wastewater represent major water usage. Efficient pumps and plumbing reduce consumption. Filtering and recycling water or converting wastewater for irrigation use helps conserve this key resource.

- Export processes use plastic bagging, foil lining, cardboard boxes, pallets, and trucks to transport coffee to ports. Optimizing packaging and transportation methods is crucial to lowering emissions.

- Strategies include using thinner, recyclable, or compostable bags, sourcing sustainable lumber for pallets, and maximizing truck loads.

- Coffee cherry pulp and wastewater can be composted or added to biodigesters to create biogas and organic fertilizer instead of methane pollution.

The Carbon Footprint of Shipping Coffee Globally

International shipping of green coffee beans is a major emissions source. While marine shipping has a lower carbon cost than air freight per pound, sea transport still produces substantial greenhouse gases.

- Sourcing coffee from origins closer to consumer markets cuts emissions from transport distance.

- Shipping in bulk Intermodal containers maximizes efficiency compared to small packaging. However reusable containers have advantages over single-use options.

- Air freight generates up to 10 times more emissions per kilogram than sea freight. But faster transit times reduce climate-controlled warehouse needs and related energy costs.

- Multi-layered mylar bags help preserve freshness but create plastic waste. Compostable natural fiber bags are an emerging alternative.

- Packaging innovations to reduce material use like thinner bags, eliminating secondary boxes, and reusable containers all lower environmental impact.

The Carbon Footprint of Roasting Coffee

Roasting also contributes to coffee’s carbon footprint through direct emissions and waste: through direct emissions and waste:

- Most commercial roasters burn natural gas, releasing carbon dioxide and nitrous oxide emissions directly into the atmosphere.

- Transitioning to renewable electricity-powered roasters eliminates direct greenhouse gases. But emissions from the electric grid must be considered.

- New roaster technologies like convection and fluid-bed models offer increased energy efficiency over traditional drum roasters.

- Roaster exhaust contains greenhouse gases. Gas separation and filtering systems can capture a portion of these emissions. Regular maintenance ensures optimal performance.

- Cooling roasted beans and controlling bean temperature until brewing require climate-controlled environments and energy for fans or air conditioning. Insulation and heat recovery systems reduce energy waste.

- Chaff and fragmented beans are roasting byproducts requiring disposal. Composting chaff for soil enrichment or biofuel feedstock gives waste new value.

The Carbon Footprint of Brewing Coffee

Home and commercial coffee brewing also contributes to overall supply chain emissions:

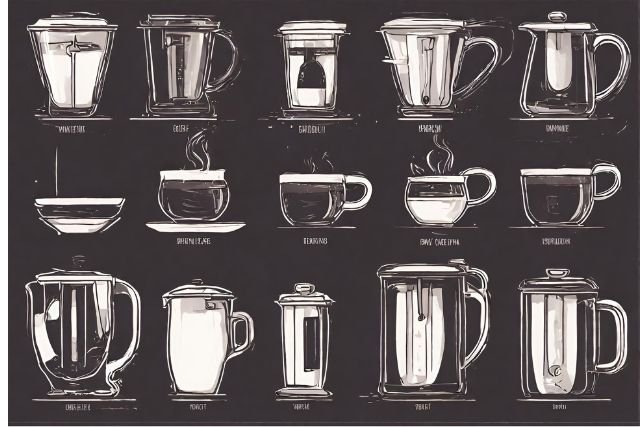

- Manual pour-over has a lower footprint than most electrical systems. Reusable options like French press and percolator have a minimal impact once purchased.

- Drip machine systems use paper filters and plastic parts but offer reasonable efficiency for everyday use.

- Espresso machines use substantial electricity and water. Super-automatic models also have integrated bean grinders, milk frothers, and other parts requiring resources.

- Single-serve pod coffee makers generate significant plastic and aluminum waste. Reusable pods or industrially compostable pods help but reduce convenience.

On the consumer end, steps like using renewable energy, minimizing plastic waste, and composting coffee grounds help lower brewing emissions.

Strategies for a Greener Coffee

There are many solutions to reduce greenhouse gas emissions across coffee production, processing, transport, roasting and brewing:

Farming Practices

- Agroforestry systems with shade trees, ground cover plants, and nitrogen-fixing cover crops

- Composting coffee pulp and farm waste to make organic fertilizer

- Mulching, crop rotation, erosion controls and efficient water use

- Renewable solar, wind or hydropower electricity

- Forest conservation and tree planting programs

Processing and Export

- Investing in renewable energy infrastructure

- Using water efficiently and treating wastewater before discharge

- Composting wet coffee pulp and husks to prevent methane pollution

- Optimizing packaging and transportation logistics

Shipping Solutions

- Sourcing coffee from origins closer to consumer markets

- Shipping in bulk containers whenever possible

- Using sea freight over air freight for lower emission intensity

- Innovations in sustainable packaging materials and reusable containers

Eco-Conscious Roasting and Brewing

- Transitioning roasters to renewable electricity models

- Installing emissions filtration systems on conventional roasters

- Energy efficient brewing systems and reusable pods

- Easy recycling programs and consumer education

Industry Collaboration and Innovation

- Supply chain partnerships to optimize logistics and share ideas

- Investments in research and development for new technologies

- Carbon labeling and lifecycle analysis to track progress

- Marketing sustainability credentials to consumers

A combination of these strategies across sectors and geographic regions is needed to make meaningful progress towards carbon neutral coffee.

| Supply Chain Stage | Sources of Emissions | Reduction Strategies |

| Coffee Farming | Deforestation, fertilizers, pesticides, electricity for processing | Sustainable agriculture, agroforestry, organic practices, renewable energy |

| Processing and Export | Electricity, fuel, biomass for drying, pulp waste, packaging | Renewable energy, waste repurposing, sustainable packaging |

| Global Shipping | Fuel for sea and air freight, port operations, packaging | Sea freight, sourcing from closer origins, packaging optimization |

| Roasting | Natural gas or electricity for roasters, roasting byproducts | Energy efficient roasters, emissions controls, waste recycling |

| Brewing | Electricity, plastic pods and packaging, grounds waste | Reusable brewing systems, consumer education on recycling |

Conclusion on the Coffee Supply Chain Carbon Footprint

With focused collaboration and innovation, the coffee sector can absolutely chart a course towards a greener, more sustainable future. But it will require ongoing commitment and effort across every link in the complex global supply chain.

From farmers to roasters, distributors to cafes, and consumers of all kinds, each has a role to play in driving down emissions through technology adoption, process changes, and conscious decision making. The challenges are certainly great, but so too is the potential.